DA66T 6+1 Axis CNC Press Brake With Feeder

Key words:

DA66T 6+1 Axis CNC Press Brake With Feeder

Classification:

- Product Description

- Components

- Technical Parameters

-

DA66T 6+1 Axis CNC Press Brake With Feeder

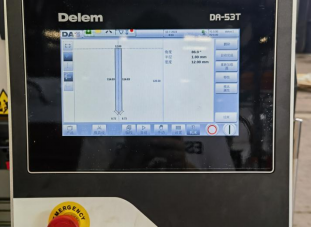

CNC/DA-66T System Introduction

Standard:

1. 2D graphical touch screen.

2. 3D visualization in simulation and production.

3. 17" color LCD display. (TFT)

4. Standard Windows functions. User specific applications support.

5. USB keyboard, mouse and flash memory drive.

6. Emergency stop device.

7. German ROSCH-REXROTH or HOERBIGER hydraulic circuit.

8. Equipped with European optical scales.

9. Precision ball screw lead, linear slide way and AC servo motor for X axis.

10. Bearing-type guideway system.

Main Function:

11. Alphanumeric product naming.

12. Automatic bending sequences calculation and setting.

13. Multi-aspect programming, graphics programming, data programming and one page programming table.

14. Millimetres/Inches, KN/Ton and languages selection.

15. Programmable material properties and axes speed.

16. Bend sequences and real-scale tooling visualization while bending.

17. Computed functions include tooling safety zones, press force, crowning adjustment, developed length, axes position, operation modes and etc.

18. Step repeat up to 99 (maximum).

19. Error messaging system.

20. Hand-wheel movement of all axes.

-

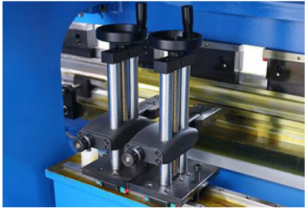

Machine parts

Fast mold clamp

CNC system

Front support + guide rail

Multi-V mold

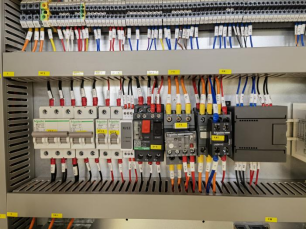

Electronic system

Hydraulic Valve

Main motor

Servo Drive

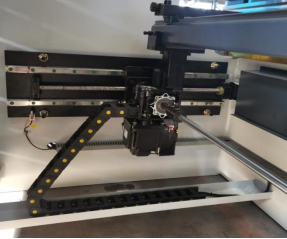

Back gauge

Double guide rail for back gauge beam

Z-axis operation finger

Ball screw + linear guide

V-axis electrical compensation

Grating ruler

Foot switch

Oil pump

Machine optional parts

CNC control system

Up and down stop finger

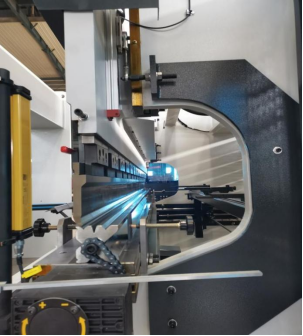

Laser protection

Air cooled

-

Get a Free Quote

We will contact you within one working day. Please pay attention to your email.

To: Company Name

Related Products