W12NC 70x4000mm sheet metal 4 roller plate rolling machine

Key words:

W12NC 70x4000mm sheet metal 4 roller plate rolling machine

Classification:

- Product Description

- Components

- Technical Parameters

-

W12NC 70x4000mm sheet metal 4 roller plate rolling machine

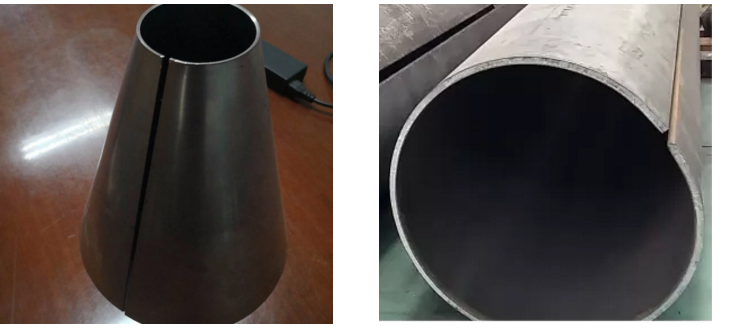

Rolling end product:

The machine belongs to a four-roll plate reel machine, used for manufacturing pressure vessels and other industries of the pre-bending, winding, and has the function of correction, rough leveling.

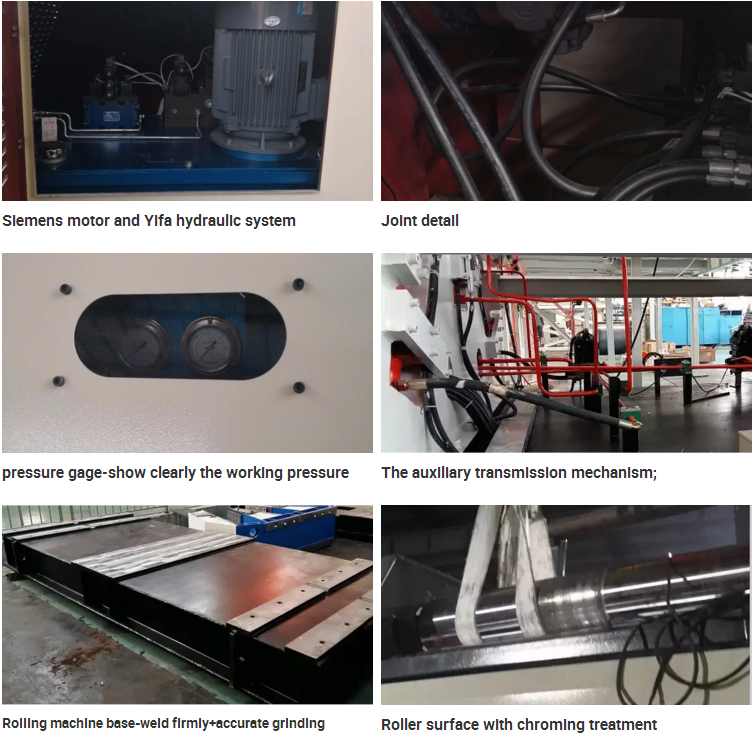

The upper roll is driven by the active roller, the lower roll, the two sides roll, the reverse head frame, and the supporting roll are driven by hydraulic pressure.The vertical lifting of the lower roll and the tilting of the side roll have the synchronization accuracy of ≤ ±0.15 mm.Pre-bending through the bottom roll, clamping the end of the plate, side roll tilt to achieve plate end bending.According to the arrangement of the two side rollers, symmetrical or asymmetric bending can be carried out, so the machine can be rolled into an ideal cylinder with small theoretical residual straight edge at one time, and it does not need to use a press to prebend the end of the plate compared with the symmetrical three-roll plate winder.

The machine is equipped with centralized grease lubrication system.The control system adopts the intelligent high speed PLC industrial control machine of OMRON Company of Japan, which controls the position of the lower roll, the two sides roll, the reverse head frame and the backup roll.

The displacement sensor of the lower roll and the two sides of the roller adopts grating. The sensor action mechanism is designed reasonably, and the service life and precision monitoring are guaranteed. All bearing pairs require the use of advanced technology, the leading products of the most well-known manufacturers. The hydraulic cylinder is made with high precision and good sealing, reducing pressure relief and leakage. The sealing device is imported.

Features compared with 4 roller bending machine:

1. Full CNC control when rolling coiling block;

2. High bending precision;

3. Improve work efficiency, save prdoction time and labor--save cost;

4.Can do cones with smaller diameter.

4 roller rolling machine details photo:

-

-

TECHNICAL PARAMETERS

Get a Free Quote

We will contact you within one working day. Please pay attention to your email.

To: Company Name

Related Products